News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

Impact crusher use and advantages

Time:2019/04/23 News List

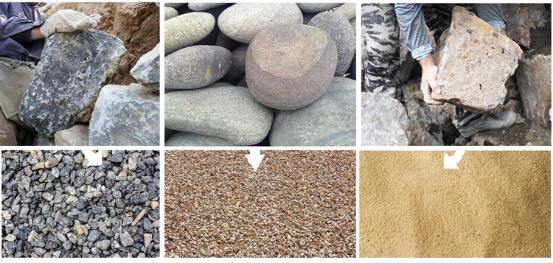

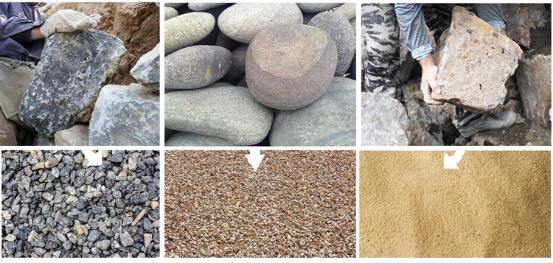

Impact crusher is mainly used to crush materials such as construction materials, metallurgy, chemical engineering, hydropower, etc., especially broken railways, roads, hydropower projects and other moving stones. Why use impact crusher? What are the advantages?

1.Impact crusher wearing parts are used for a long time

1.Impact crusher wearing parts are used for a long time

The wear of the impact crusher plate hammer is only present on the side facing the material. When the rotor speed is normal, the material will fall on the surface of the hammer, and the back and sides of the hammer will not be worn, even if it is worn on the side of the material. And the bottom grinding rod is also easy to replace. The metal utilization rate of the impact crusher plate hammer can be as high as 45% - 48%.

2. the impact crusher discharge particle size is adjustable

2. the impact crusher discharge particle size is adjustable

The impact crusher has obvious advantages in the adjustment of the discharge size. The impact crusher has obvious advantages in adjusting the discharge particle size. Compared to other crushers that adjust the size of the discharge opening to adjust the discharge size, the counter-break can be adjusted in three ways. First, adjusting the speed or diameter of the rotor, increasing the speed of the rotor, or increasing the diameter of the rotor at the same speed can increase the pulverization time. Secondly, by adjusting the feeder to change the particle size of the product, the residence time of the material particles in the crushing chamber is shortened, and the production capacity of the crusher is improved. Third, adjust the gap of the grinding chamber to change the particle size of the finished product. The gap adjustment of the grinding chamber is mainly carried out by mechanical or hydraulic type, and the hydraulic type can quickly and conveniently operate the button or the control system to complete the gap adjustment.

3. Impact crusher’s models of various types, easy to configure

3. Impact crusher’s models of various types, easy to configure

The impact crusher produced by our company has complete specifications, and can adopt various configurations according to the nature of the crushed materials, the scale of operation and the requirements of finished products, to meet the needs of users to a large extent.

4. The impact crusher has simple structure and convenient maintenance.

4. The impact crusher has simple structure and convenient maintenance.

Only six hammers are installed on the rotor of the impact crusher. The special tools provided by our company can be used to replace the hammers. It takes only one shift to replace one set of hammers. The replacement of the grinding rods only takes tens of minutes. Therefore, the time for inspection and replacement can be greatly reduced.

The wear of the impact crusher plate hammer is only present on the side facing the material. When the rotor speed is normal, the material will fall on the surface of the hammer, and the back and sides of the hammer will not be worn, even if it is worn on the side of the material. And the bottom grinding rod is also easy to replace. The metal utilization rate of the impact crusher plate hammer can be as high as 45% - 48%.

The impact crusher has obvious advantages in the adjustment of the discharge size. The impact crusher has obvious advantages in adjusting the discharge particle size. Compared to other crushers that adjust the size of the discharge opening to adjust the discharge size, the counter-break can be adjusted in three ways. First, adjusting the speed or diameter of the rotor, increasing the speed of the rotor, or increasing the diameter of the rotor at the same speed can increase the pulverization time. Secondly, by adjusting the feeder to change the particle size of the product, the residence time of the material particles in the crushing chamber is shortened, and the production capacity of the crusher is improved. Third, adjust the gap of the grinding chamber to change the particle size of the finished product. The gap adjustment of the grinding chamber is mainly carried out by mechanical or hydraulic type, and the hydraulic type can quickly and conveniently operate the button or the control system to complete the gap adjustment.

The impact crusher produced by our company has complete specifications, and can adopt various configurations according to the nature of the crushed materials, the scale of operation and the requirements of finished products, to meet the needs of users to a large extent.

Only six hammers are installed on the rotor of the impact crusher. The special tools provided by our company can be used to replace the hammers. It takes only one shift to replace one set of hammers. The replacement of the grinding rods only takes tens of minutes. Therefore, the time for inspection and replacement can be greatly reduced.

- Recommended News

- Expo 2020 Dubai as well as Henan Week in China Pavilion opened in the same time in both online and off line

- Mobile gold trommel washing plant

- The Nile Machinery was invited to participate in the China-Zambia Economic and Trade Forum

- LETTERS OF PATENTS

- CERTIFICATE&HONOR

- The Nile Machinery won the Zhengzhou E-commerce Innovative Person Award

- Can the production capacity of sand making equipment not meet expectations? Mainly these five factors

- What is a mine production line? What are the main points of the design of the mine production line?

- What are the machines that make stones? Stone production process

- Can the production capacity of sand making equipment not meet expectations? Mainly these five factors

Recommended Products

More

More