News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

Introduction of Jaw Crusher

Time:2021/07/20 News List

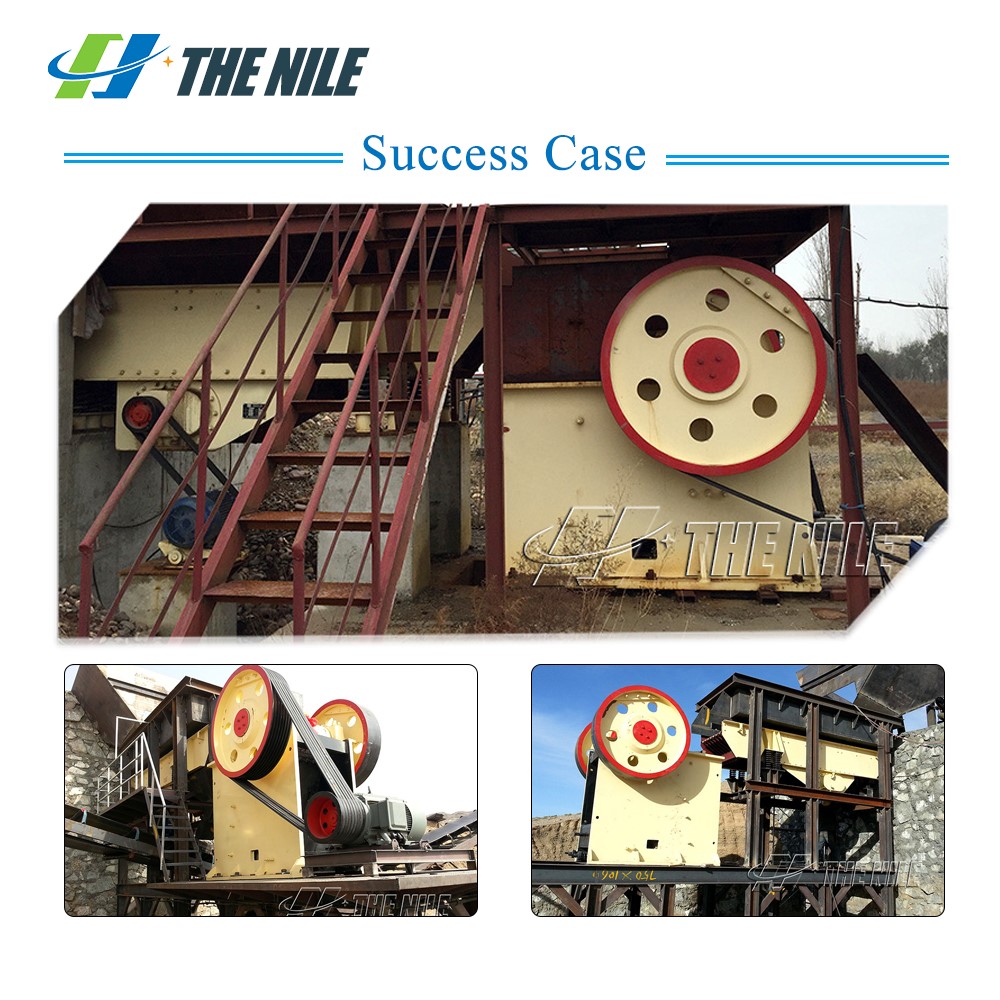

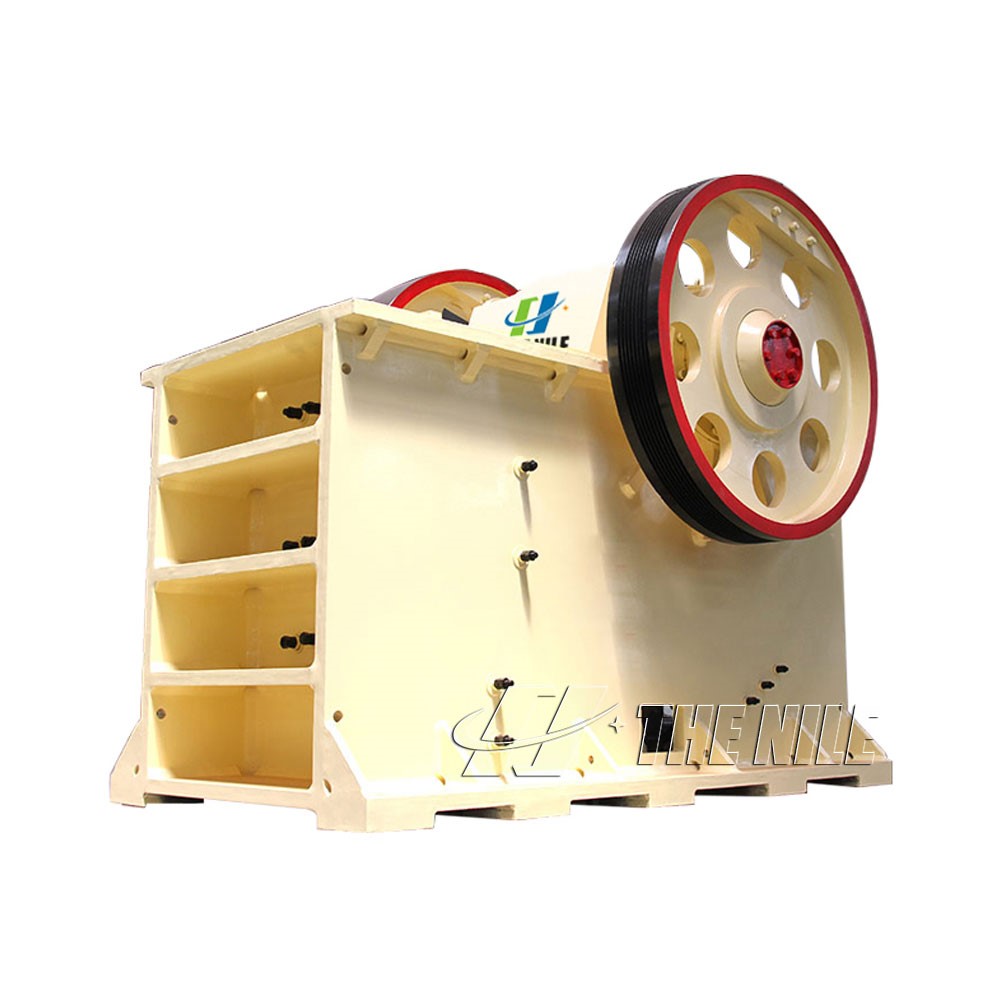

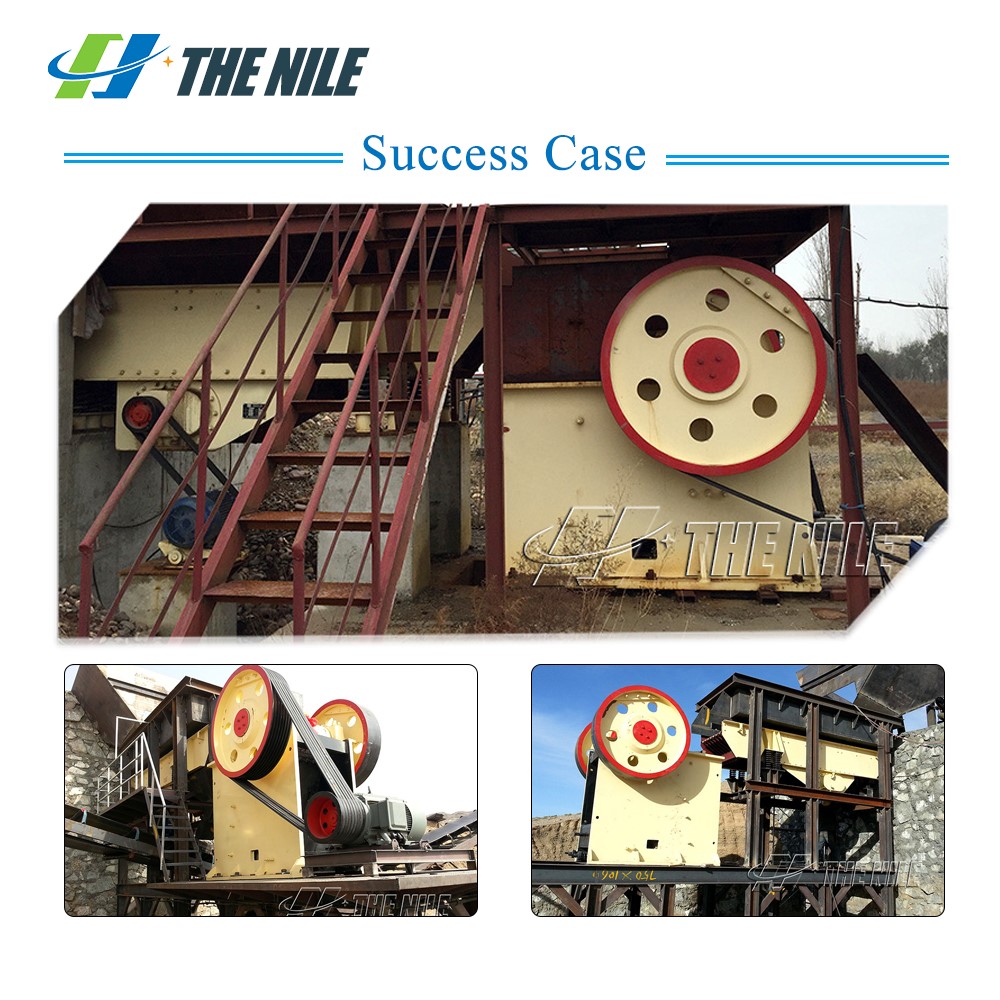

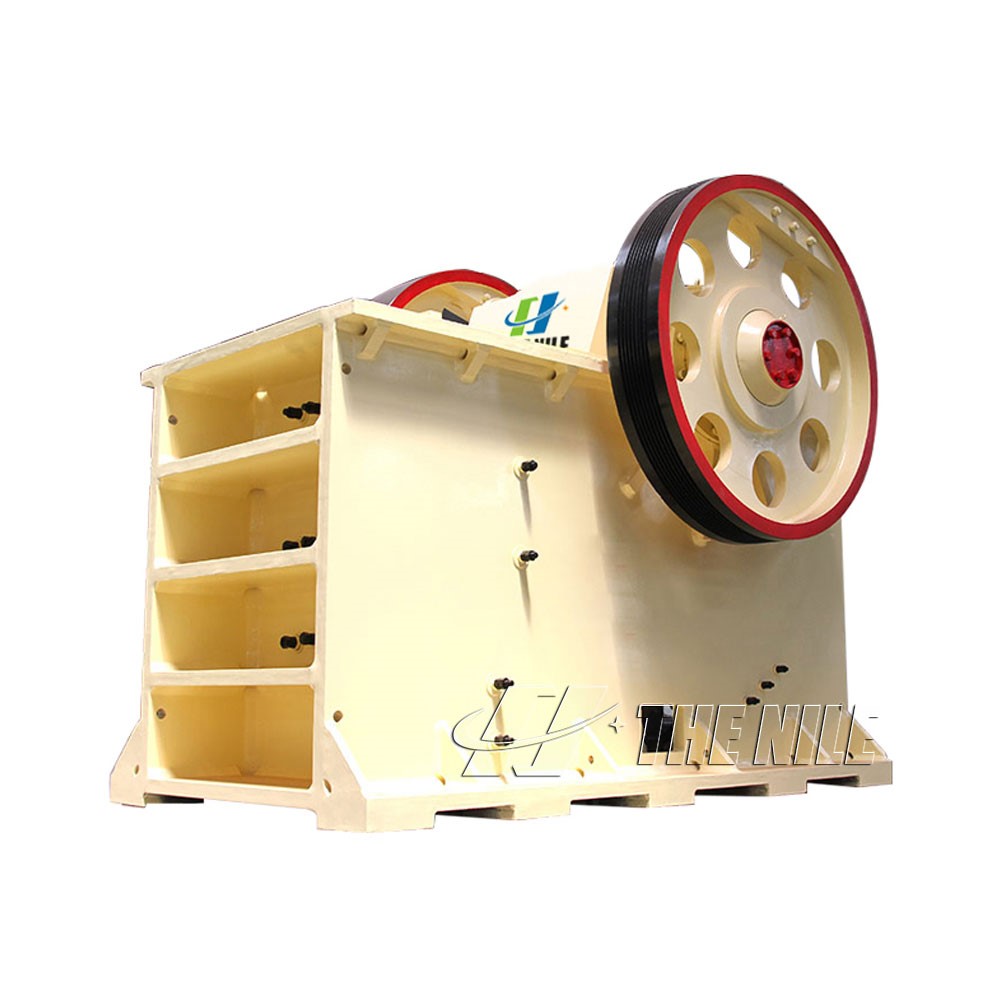

Jaw crusher is a relatively large equipment currently in demand. It is used as primary crusher and secondary crusher. This kind of stone jaw crusher machine can be used to crush all materials with compressive strength below 320Mpa, such as basalt, granite, marble, limestone, etc.

Jaw crushers are currently widely used in mining, smelting, building materials, highways, railways and other industries with a wide range of applications.

Jaw crushers are currently widely used in mining, smelting, building materials, highways, railways and other industries with a wide range of applications.

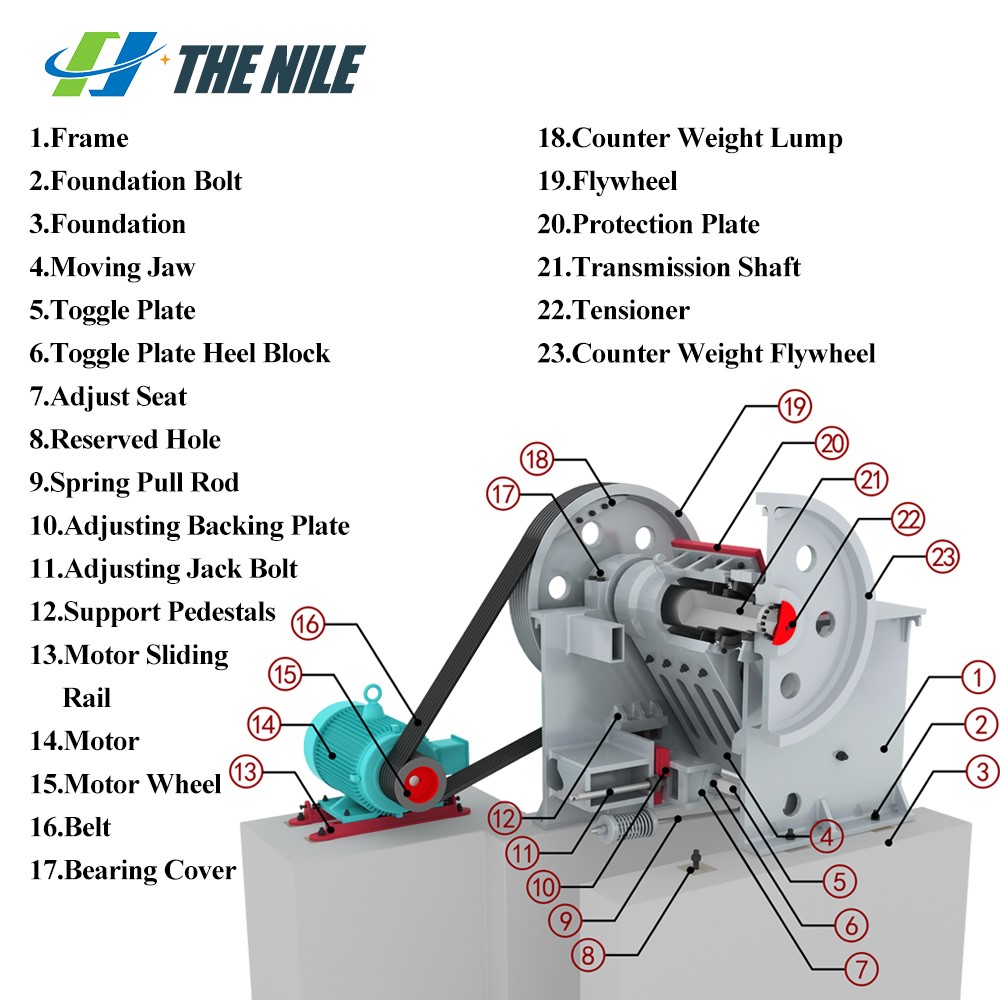

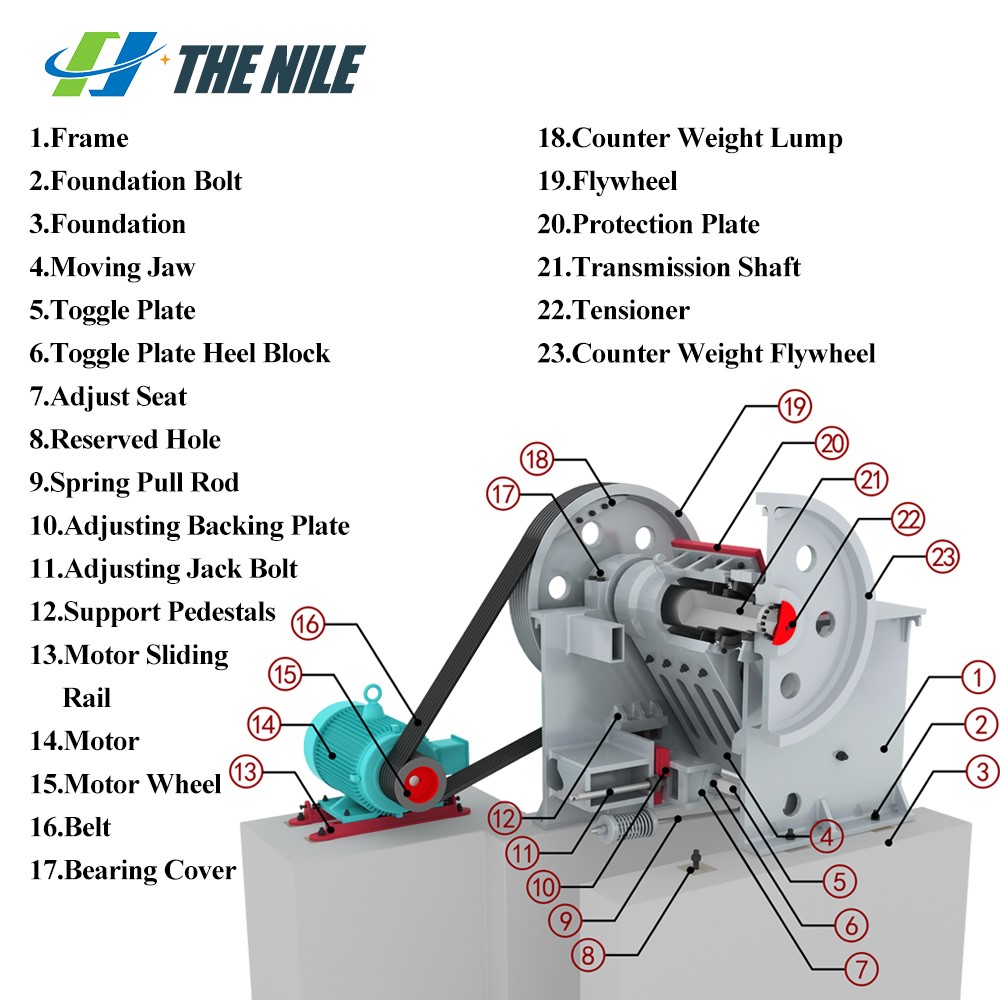

The jaw stone crushing machine is mainly composed of the frame part, the eccentric shaft rotation part, the working part of the crushing chamber, the safety device, the discharge opening adjustment device, etc., among which the toggle plate side guard, the movable jaw, the static jaw spring bearing, the triangle belt, the toggle pad, etc. These are fragile parts and should pay attention to daily maintenance. Good maintenance can extend the service life of jaw crusher equipment.

The jaw stone crushing machine is mainly composed of the frame part, the eccentric shaft rotation part, the working part of the crushing chamber, the safety device, the discharge opening adjustment device, etc., among which the toggle plate side guard, the movable jaw, the static jaw spring bearing, the triangle belt, the toggle pad, etc. These are fragile parts and should pay attention to daily maintenance. Good maintenance can extend the service life of jaw crusher equipment.

working principle of jaw crusher

working principle of jaw crusher

Driven by the motor as the power source, the motor inputs the power to the pulley through the V-belt, and the pulley drives the eccentric shaft to rotate.Drive the movable jaw body to swing back and forth up and down. When the movable jaw moves close to the fixed jaw, the volume of the crushing cavity decreases, and the material in the crushing cavity is squeezed or broken. When the movable jaw moves away from the fixed jaw, the volume of the crushing cavity becomes larger and the crushing cavity The crushed small pieces of material are discharged from the discharge port, through this continuous circulation movement, the crushing operation is realized.

Advantages

Advantages

1. Simple structure, easy operation and convenient maintenance

2.Jaw stone crusher has large crushing ratio, uniform product size

3. Reliable performance and stable output

4. Low cost, less dust and low noise

5. A wide range of crushed materials, all materials with compressive strength below 320Mpa can be crushed by The Nile brand jaw crusher machine.

Better quality from Top supplier, this kind fo jaw crusher produced by The Nile has good quality and attractive prcie, welcome to contact us and visit our factory!

Driven by the motor as the power source, the motor inputs the power to the pulley through the V-belt, and the pulley drives the eccentric shaft to rotate.Drive the movable jaw body to swing back and forth up and down. When the movable jaw moves close to the fixed jaw, the volume of the crushing cavity decreases, and the material in the crushing cavity is squeezed or broken. When the movable jaw moves away from the fixed jaw, the volume of the crushing cavity becomes larger and the crushing cavity The crushed small pieces of material are discharged from the discharge port, through this continuous circulation movement, the crushing operation is realized.

1. Simple structure, easy operation and convenient maintenance

2.Jaw stone crusher has large crushing ratio, uniform product size

3. Reliable performance and stable output

4. Low cost, less dust and low noise

5. A wide range of crushed materials, all materials with compressive strength below 320Mpa can be crushed by The Nile brand jaw crusher machine.

Better quality from Top supplier, this kind fo jaw crusher produced by The Nile has good quality and attractive prcie, welcome to contact us and visit our factory!

- Recommended News

- Expo 2020 Dubai as well as Henan Week in China Pavilion opened in the same time in both online and off line

- Mobile gold trommel washing plant

- The Nile Machinery was invited to participate in the China-Zambia Economic and Trade Forum

- LETTERS OF PATENTS

- CERTIFICATE&HONOR

- The Nile Machinery won the Zhengzhou E-commerce Innovative Person Award

- Can the production capacity of sand making equipment not meet expectations? Mainly these five factors

- What is a mine production line? What are the main points of the design of the mine production line?

- What are the machines that make stones? Stone production process

- Can the production capacity of sand making equipment not meet expectations? Mainly these five factors

Recommended Products

More

More